After the spring break, I had to recap myself what I have learned. So I skimmed though the class webpage.

I grabbed the material that is thick. I looked for the thickness first which later gave me a hard time.

Since the thickness of the aluminum rod was too thick, I changed the teeth of the lathe to the other form. Getting them back in the right position was hard that one at the bottom was loose due to the gravity. So, I tightened them with my hand as screwing the chuck key. And in order to check the safety I tightened them to the maximum.

After the teeth were fit, I placed the rod and started facing. Since the rod was cut not in flat I faced it. It took a lot of oiling, stop and check.

As I face the surface I noticed that the rod was not cutting flat on the outer edge. So I faced from the inside to the outside instead of from the outside to the inside. And the result was good.

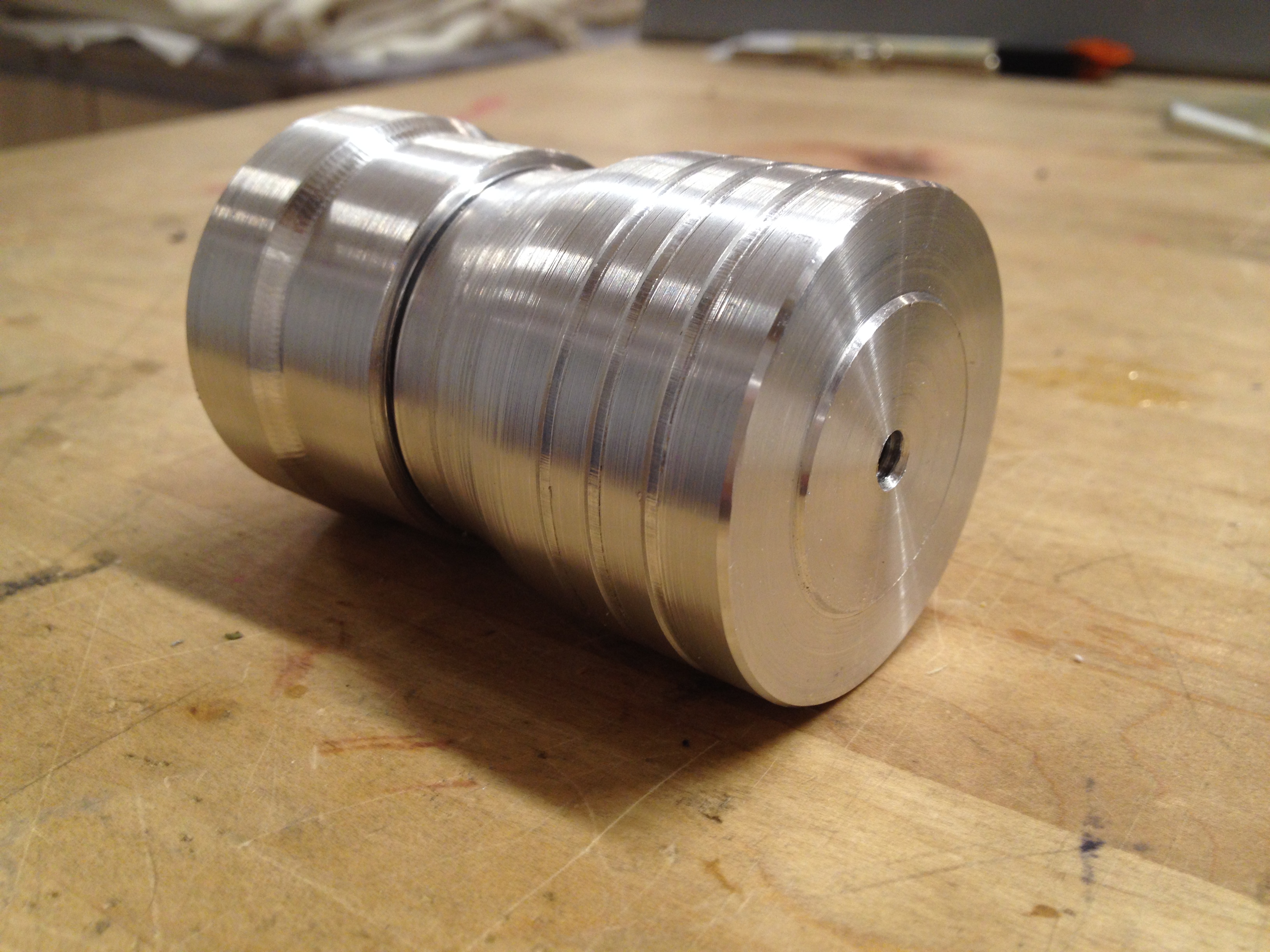

After the facing, I did turning and marked the line that I could turn as I am turning to keep myself safe.

After turning, I marked the design that I wanted to make and I used parting tool and turing tool to making it. After finishing the turning, I drilled the hole at the center. First I used the center bit to mark the center. I used 4 drill bits to get the right size from the chart.

After threading, I wanted to cut the piece into half. I used parting tool to cut then, at the middle of process I was little scared. The piece that I was about to cut was heavy and I was not confident whether the WD40 plastic pipe would catch it. So, I stopped the lathe and cut the other end with the metal saw. The piece was too small to fit in the metal saw. So I tried to cut just 1/4 of the piece. And as I finished cutting, the other piece flew to the plastic container. That was really a scary moment. So later, I would just use the lathe facing the piece to shorten it. So I finished the piece and made the thread with tapping tool.

After finishing, I found that I actually made a hole through as I am making the tap. Here is the result.