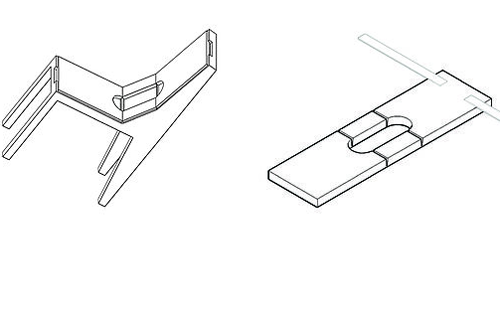

So I wanted to make a simple clothes hanger. I wanted to make it by press-fit structure. I measured the thicknesses,width and height of the board before sketching at the Vectorworks/AutoCAD.

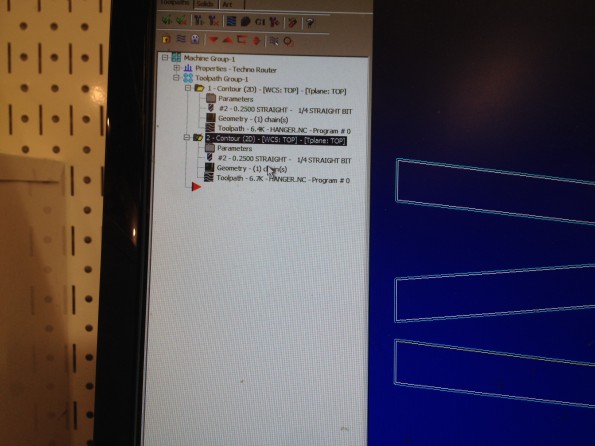

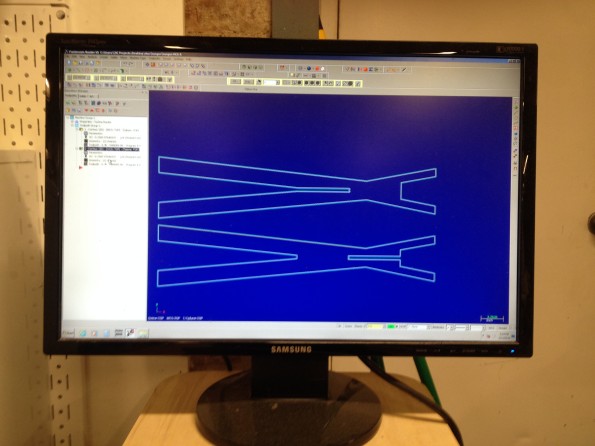

From the measurements, I made a square 48 inch by 24 inch and squished the design into this square. As I am working on the Vectorworks I found difficulty getting used to the joining lines. So, I re-sketched on the AutoCAD which I am comfortable with. After making the DWG/DXF file, I re-opened the file in the Vectorworks to make sure. At the MasterCam I managed to make a nice file and generated G-code.

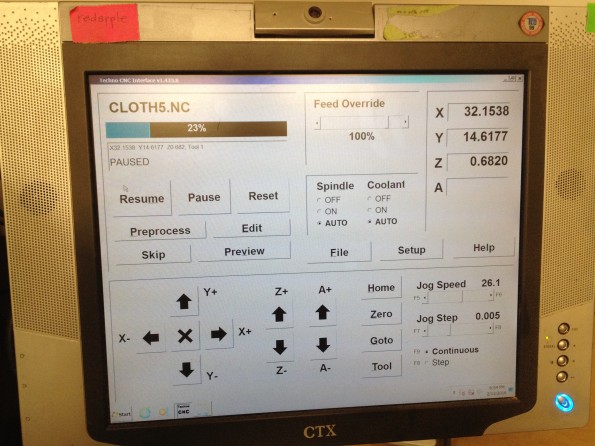

I set the board on the bed, loaded milling bit and from the CNC interface software I zeroed XYZ axes. After that, I clicked the preview and the preprocess and started.

Surprisingly, at the beginning when the machine was checking its movement it was trying to go to the end of Y axis. I stopped and looked back the file again at the MasterCam and the Vectorworks. I tried one more and it still did that strange movement. So, I looked carefully and found at the preview that the origin was far off. So the machine wanted to go to the far outside of the bed.

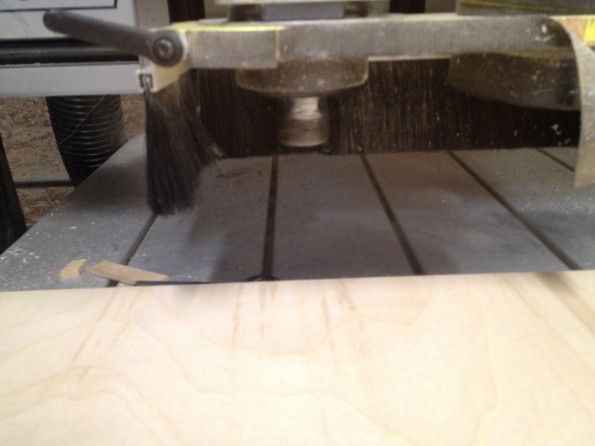

I opened the file again at the Vectorworks and I found the origin of XY was not at the center of the workpage by drawing a line with the staring point (0,0). It was at the left bottom corner. So, I moved drawings close to the origin and regenerated the G-code. And It was not cutting again. The bit was in the air. So, I quickly caught that I did put the positive number at the Cut Depth. So, I revisit the CamMaster and changed the number with the negative number and regenerated the G-code. Now it was cutting well. As it is cutting I vacuumed the debris.

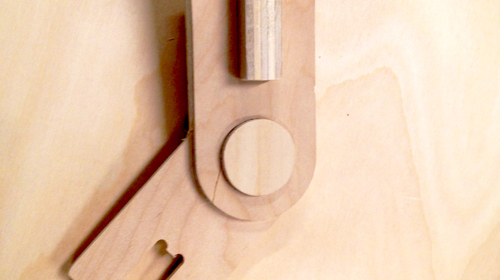

During the cutting when the bit enters the press-fit area it made a loud noise. I paused the CNC and examined it. Since the press-fit area was too tiny the wood was cracked in the middle of the layer and it was shaking. So, I broke it away from the bit and continued the work. So, for the second round when it was almost done, I paused the machine and removed the piece beore it gets creacked. You can see them here. I sanded the final pieces and assembled them together.

Finished.